Modular Connection Node Development

Role: Lead Mechanical & Structural Engineer

Organization: Assembly OSM

Objective: Design and engineer a proprietary connection system enabling vertical stacking of modular apartment units with full code compliance and structural redundancy

During my time at Assembly OSM, I played a lead role in the design, finite element analysis (FEA), and development of a proprietary structural node system that revolutionized how modular apartment units could be connected, transported, and assembled in dense urban environments. The project focused on creating a scalable, factory-built construction system capable of meeting New York City’s stringent structural and building codes, while maintaining the precision, repeatability, and transport efficiency required for modular manufacturing.

Concept and Function of the Proprietary Connection Node

The connection node I developed serves as the core structural interface between prefabricated steel apartment modules, allowing units to be stacked vertically and joined laterally while transferring both axial and lateral loads safely through the structure.

This node forms the primary load path between floors and modules, ensuring that all compressive, tensile, and moment forces are resolved at predictable, engineered contact points.

The design integrates a patented steel bushing assembly and precision-machined bearing interfaces, which together maintain alignment tolerances during assembly while reducing shear distortion between modules. The node system was designed to meet AISC 360, NYC DOB, and 1 RCNY §101-07 structural requirements for prefabricated and modular structures.

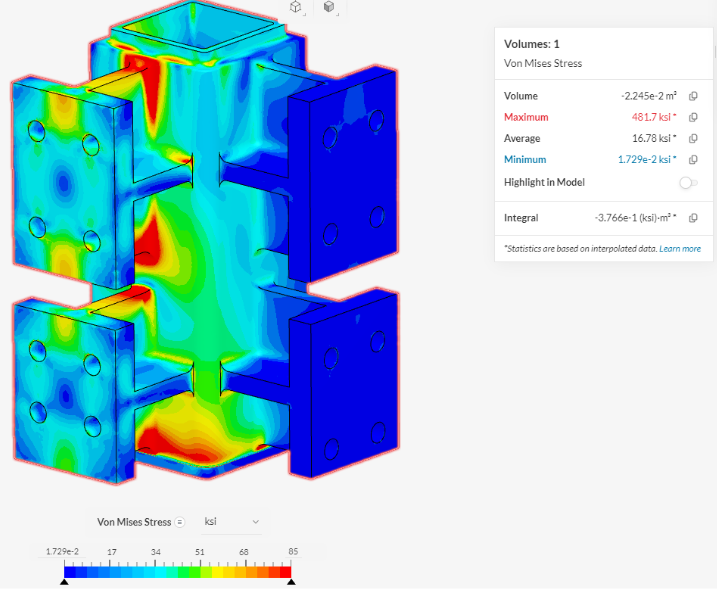

Structural Engineering & FEA Analysis

I led the structural modeling efforts using SolidWorks Simulation and ANSYS FEA, performing a series of nonlinear load tests and buckling analyses on the connection node and surrounding chassis frame.

These analyses quantified stress concentration zones and confirmed elastic stability under combined load cases, including dead load, live load, wind uplift, and lateral drift conditions per Manhattan wind and seismic code provisions.

Key analysis outputs included:

Load path validation under corner stacking scenarios up to multi-story configurations.

Contact stress optimization between the bushing and node surfaces to minimize localized yielding.

Shear transfer tests through full-scale mockups to confirm theoretical predictions within ±5% of FEA results.

These studies guided revisions to the node geometry, introducing filleted transitions, gusset reinforcements, and bolt preloading procedures that improved both structural performance and ease of assembly.

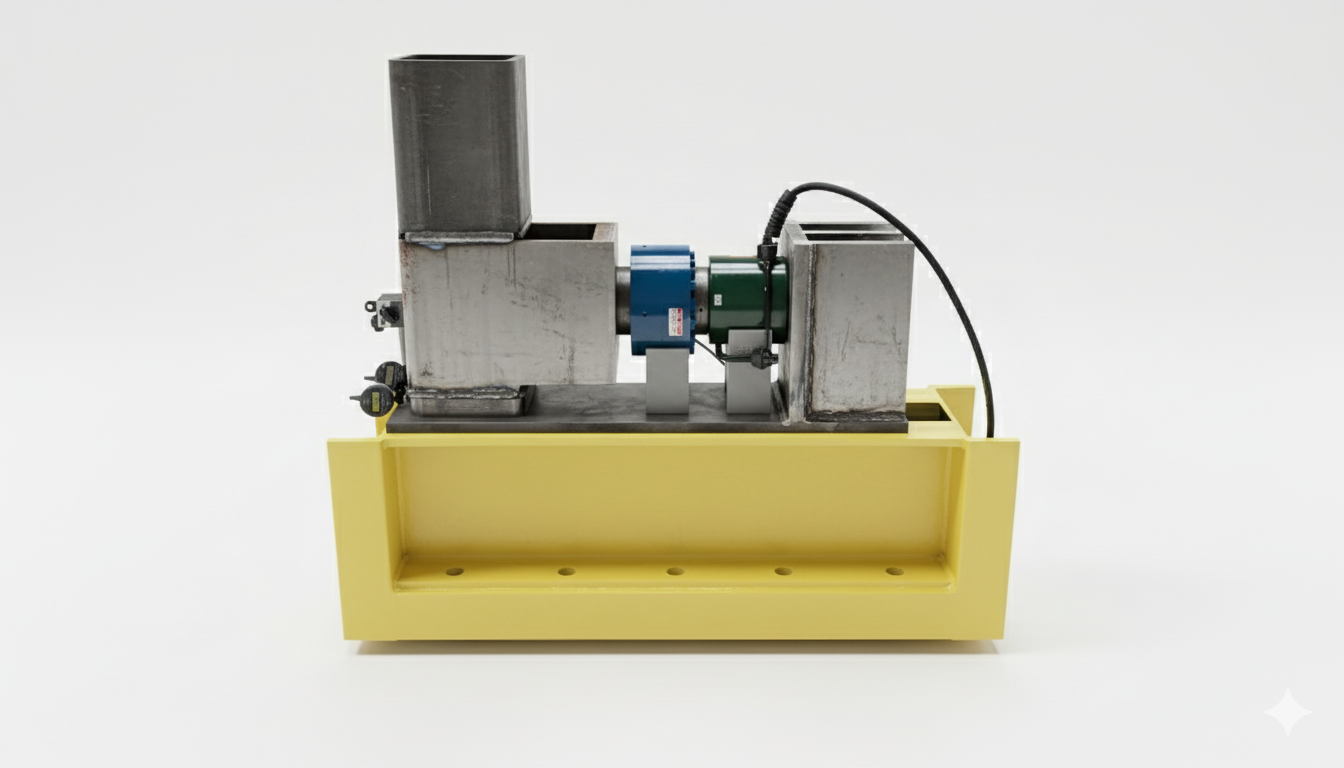

Prototyping and Hardware Development

To support field assembly and full-scale validation, I developed precision prototypes of the node and its associated steel bushing hardware, machined to tight tolerances.

Each node was fabricated from A572 Grade 50 structural steel with CJP (Complete Joint Penetration) welds verified by ultrasonic testing. The integrated bushing system was machined from 4140 alloy steel, selected for its high fatigue strength and surface hardenability, and was designed to distribute load evenly across the mating interfaces while allowing repeatable alignment during stacking.

Prototype evaluation occurred both in the fabrication shop and in Assembly OSM’s large-scale test facility, where the connection node was instrumented with strain gauges and subjected to real load tests using hydraulic actuators to simulate stacked module forces. The successful results demonstrated high structural integrity, low deflection rates, and exceptional repeatability across multiple installations.

System Integration and Code Compliance

Beyond structural design, I worked closely with building code consultants, licensed structural engineers, and DOB compliance officers to align the connection node with New York City modular building standards.

This included documentation for Special Inspections (SI) under the NYC Building Code and testing protocols for on-site module alignment verification.

My work contributed directly to obtaining prototype approval for stacking modular units in Manhattan, a milestone for the company’s urban modular housing program.

Chassis Development and Modular Unit Integration

In parallel with the node, I engineered the structural steel chassis of the modular units themselves — effectively the load-bearing skeleton that the node system interfaces with. The chassis was optimized for fabrication simplicity, transportation stiffness, and modular scalability.

Using FEA-driven optimization, I developed a cross-braced configuration that balanced stiffness and weight for both transport-induced vibrations and lifting stresses during craning operations.

The final chassis design ensured minimal deflection during rigging, hoisting, and stacking, supporting Assembly OSM’s goal of precision modular assembly within ±3 mm alignment tolerance across stacked units.

Fabrication and Field Implementation

The full-scale connection nodes were fabricated and assembled at Assembly OSM’s manufacturing site in Kearny Point, then tested and deployed in pilot modular assemblies.

The photographs shown depict:

The machined prototype node assembly with integrated bolts, bushings, and welded gussets.

In-house load testing setup on a calibrated steel test rig used for validation.

Full-scale modular chassis lifting operations inside the historic Kearny Shipyard hangar, demonstrating the modular stacking sequence.

The finished modular unit, fully enclosed and fitted with interior finishes, ready for transport and installation.

Outcome and Impact

This project resulted in the creation of a new class of high-strength, precision-engineered connection hardware enabling modular buildings to be constructed faster, safer, and with greater accuracy than traditional methods.

My invention of the proprietary connection node and bushing system laid the foundation for Assembly OSM’s modular stacking technology, paving the way for scalable, code-compliant high-rise modular housing in one of the most demanding construction environments in the world — New York City.

Structural Modular Chassis

Modular Unit Interior

Structural Connection Node Assembly

FEA of Node Connection

Structural Connection Bolt + Bushing Assembly

Ultimate Compressive Load Test Machine