Peloton Tread Deck Inversion Fixture

Role: Mechanical Design Engineer

Organization: Peloton

Objective: The primary objective of this project was to design and fabricate a mechanical inversion fixture capable of allowing a single operator to rotate a full Peloton treadmill deck 180 degrees with minimal effort, enabling easy access to the underside of the deck during the refurbishing process.

The goal was to significantly reduce ergonomic strain, labor hours, and operational bottlenecks associated with manual flipping, while ensuring repeatable alignment, structural stability, and shop-floor robustness.

The project was executed with an extremely aggressive timeline—three weeks from concept to a fully functional prototype, including CAD design, stress evaluation, fabrication, assembly, and initial operator trials.

System Design and Structure

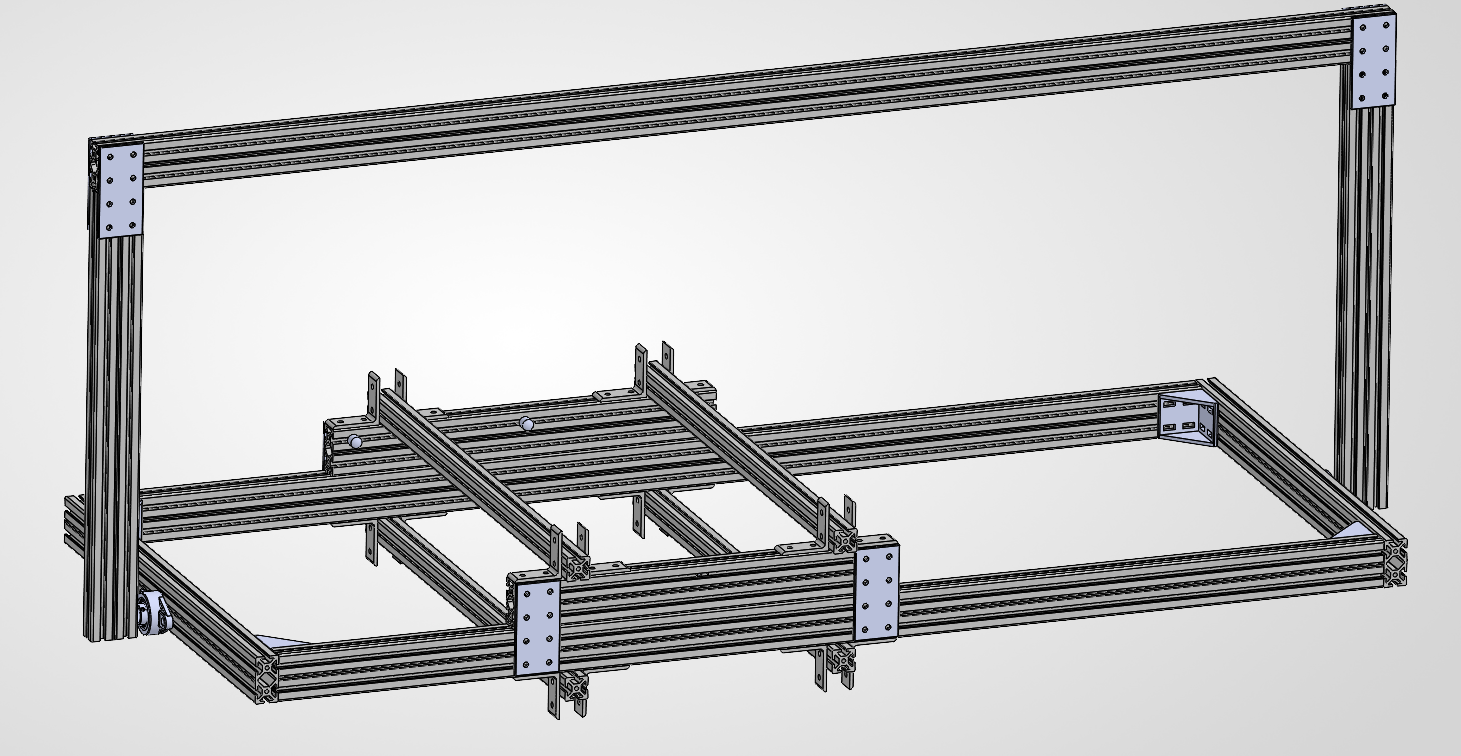

The inversion fixture was engineered as a modular, rigid, and ergonomically optimized system constructed primarily from industrial T-slot aluminum extrusion. This structural choice enabled high stiffness-to-weight ratio, ease of assembly, and adjustability to accommodate multiple treadmill deck revisions.

Key structural elements included:

Two longitudinal support rails configured to capture the tread deck’s frame and distribute loads evenly during rotation

Bearing-mounted pivot axles anchored to reinforced extrusion nodes, allowing smooth, controlled 180° rotation

Adjustable lateral supports to stabilize different deck geometries

Locking detents and safety stops to secure the deck at both the upright and inverted positions

Rigid base interface compatible with shop pallets, jack stands, and mobile carts

The design emphasized operator safety and controlled kinematics, ensuring that the treadmill deck remained stable through the entire rotational arc while minimizing the torque required at the pivot point.

Design and Validation Using SolidWorks and FEA

The complete system was developed in SolidWorks, starting with conceptual sketches and progressing to a fully parametric 3D assembly.

Engineering validation included:

Load-path analysis to ensure the T-slot structure could withstand dynamic moments during inversion

Finite Element Analysis (FEA) of pivot joints, bearing housings, and extrusion nodes to assess stress concentrations under the worst-case load condition

Deflection analysis to confirm allowable flex limits under deck mass and operator-induced loads

Bolt pattern and fastener preload evaluation per typical industrial design practices

Design iterations focused on optimizing stiffness, minimizing part count, and ensuring manufacturability using readily available off-the-shelf hardware.

Prototype Fabrication and Assembly Coordination

Following final design approval, I led the full fabrication and assembly effort.

Key activities included:

Generating detailed machining prints and cut lists for extrusion, brackets, and reinforcement plates

Coordinating procurement of bearings, brackets, aluminum extrusion, and specialized fasteners

Overseeing precision cutting, drilling, tapping, and deburring operations

Assembling the full fixture, including pivot bearing installation, structural square-up, and torque verification of all mechanical joints

Performing iterative adjustments to improve deck fit, pivot smoothness, and locking accuracy

The assembled prototype matched the CAD model with high fidelity and required minimal post-build tuning.

Testing and Performance

Once assembly was complete, the fixture underwent a series of operational tests to evaluate:

Rotational smoothness under full deck load

Required operator force for inversion

Stability during deck support and flip cycles

Clearance constraints between frame elements and treadmill housing

Rigidity and recovery after repeated cycles

Testing confirmed that a single operator could safely and comfortably rotate the treadmill deck with minimal physical effort—transforming what was previously a multi-person, high-risk operation into a repeatable, ergonomic process.

Additionally, the fixture demonstrated excellent structural rigidity, with no detectable permanent deformation after repeated flip cycles.

Technical Impact and Legacy

The inversion fixture produced immediate and measurable value for Peloton’s refurbishing operations:

+60% reduction in labor time required to access the underside of a deck

Elimination of two-person lifting requirements, improving safety compliance

Higher throughput for the refurbishing line

Reduced operator fatigue and injury risk

Lower operational cost per refurbished treadmill, improving refurb profitability

Beyond its immediate functional benefits, the project demonstrated the ability to deliver rapid, high-value mechanical solutions within extremely tight timelines—leveraging advanced CAD modeling, FEA validation, hands-on fabrication expertise, and a deep understanding of production-floor logistics.

This fixture now serves as a model for future workflow-optimization tools within Peloton’s operations engineering efforts.

Peloton Tread Deck Inversion Fixture (CAD)

Prototype Build On-Site

Locking Fixture Design

Frame Stability Test

Prototype Performance Test