High Speed Drone Development

Role: Senior Mechanical Engineer / Hardware Lead

Organization: Drone Racing League (DRL)

Objective: Design and develop a next-generation speed drone targeting the Guinness World Record for the fastest drone

During my time with the Drone Racing League, I led the mechanical design and full hardware development of a next-generation speed drone platform engineered for extreme aerodynamic performance and structural efficiency. My primary focus was the design, optimization, and validation of the canopy and chassis—two critical components responsible for aerodynamic drag reduction, cooling efficiency, and structural rigidity under high-thrust conditions.

Aerodynamic Design & CFD Optimization

I conducted extensive Computational Fluid Dynamics (CFD) simulations using SimScale to refine the drone’s external geometry, particularly around the aerodynamic canopy and arm junctions. The goal was to minimize pressure drag while maintaining sufficient cooling airflow through the internal electronics bay housing the power distribution board, ESCs, and high-density 5S LiPo battery pack.

By iterating through multiple canopy profiles and arm fairing geometries, I identified configurations that reduced overall drag coefficients while improving stability at extreme velocities. Each iteration was validated through parametric SolidWorks models that linked geometric changes to flow simulation results, ensuring a fully data-driven design workflow.

Structural Design & Material Selection

I designed the modular chassis and canopy system in SolidWorks, balancing strength, weight, and manufacturability. The prototype structure was 3D printed using the Bambu Labs X1 Carbon printer, leveraging high-performance filament materials such as PA-CF (carbon fiber reinforced nylon) and ASA. These materials were chosen for their thermal stability, impact resistance, and stiffness-to-weight ratio, ensuring the frame could withstand both aerodynamic forces and heat generated by the motors and internal electronics.

I also performed Finite Element Analysis (FEA) to verify arm stiffness and canopy mount points under simulated aerodynamic and inertial loads. The final prototype demonstrated improved structural rigidity without increasing mass, a critical balance for achieving the target thrust-to-weight ratio and speed stability.

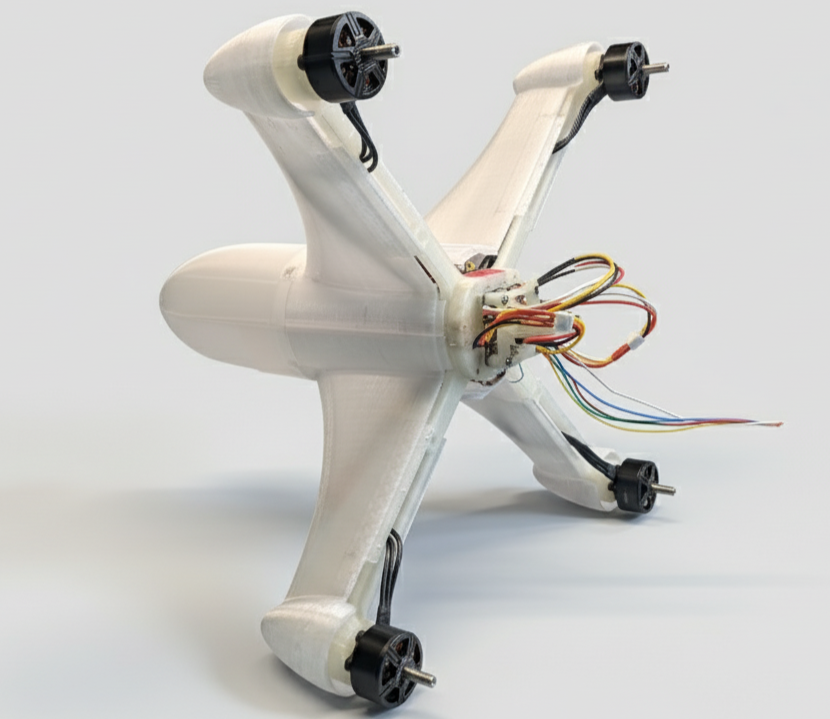

Prototyping & System Integration

As the hardware lead, I oversaw the complete prototype development cycle—from 3D printing and assembly to bench-level validation testing. I implemented thermal and vibration isolation strategies around the flight controller and PCBs to ensure signal stability at high rotational speeds. The internal layout of the drone was optimized for center of gravity balance, cooling airflow, and ease of component servicing.

Path to Production

The long-term goal was to transition from a prototype platform to a production-ready version featuring a thermoformed or injection-molded thermoplastic canopy and a CNC-machined carbon fiber chassis. These material upgrades would allow for improved repeatability, strength, and aerodynamic consistency across production units—necessary for official record attempts and standardized performance testing.

Outcome

This project represented a significant step toward pushing the aerodynamic and structural limits of multirotor drone design. By integrating simulation-driven optimization, advanced additive manufacturing, and materials engineering, I was able to deliver a high-speed prototype that informed DRL’s next generation of performance drone platforms designed for record-setting flight speeds.

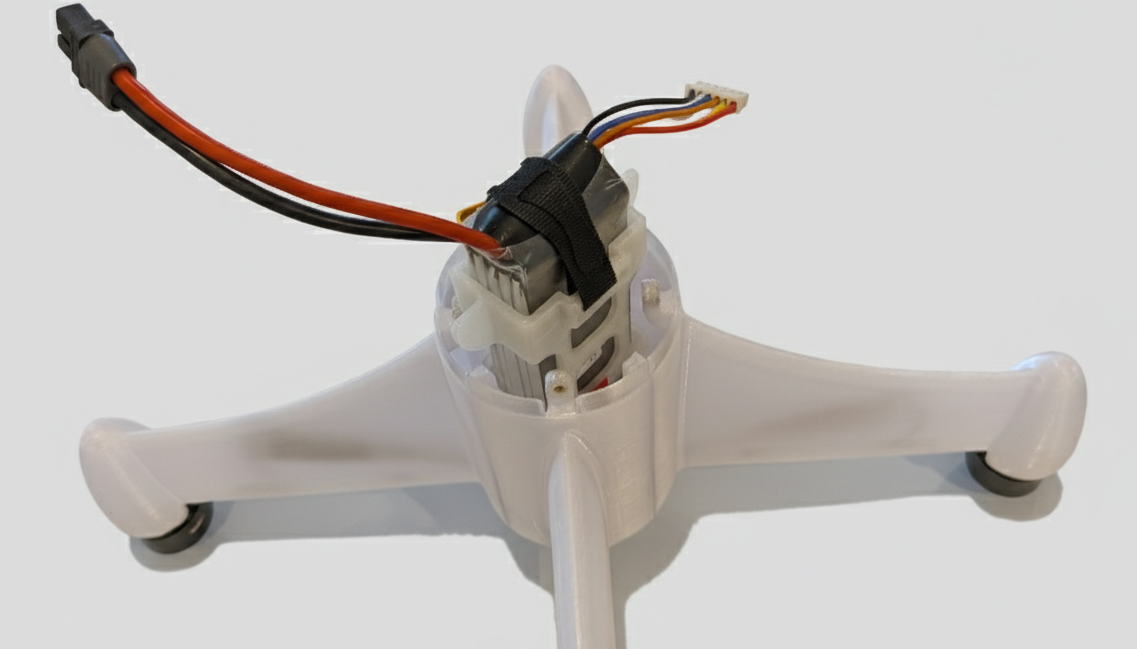

Battery Chassis Design

Gyro calibration of speed drone

Canopy + Chassis Integration

Production Units

CFD Analysis of Canopy

Prototype Unit with Propellers